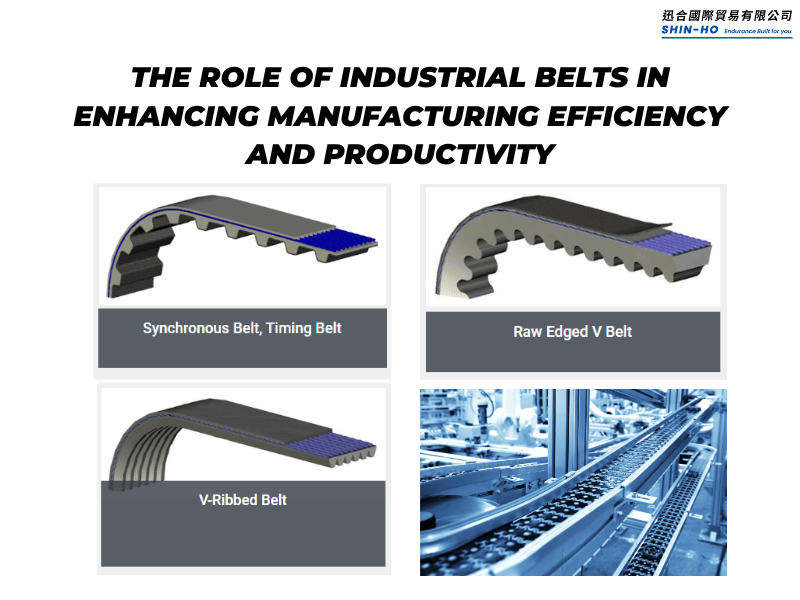

The Role of Industrial Belts in Enhancing Manufacturing Efficiency and Productivity

In the modern manufacturing world, efficiency and productivity are not just goals—they're necessities. As industries continue to automate and scale operations, every component in a production line must perform reliably and effectively. Among these critical components, industrial belts play a surprisingly central role. Though often overlooked, the right industrial belt can directly influence machine uptime, energy use, and product quality.

At Shin-Ho International Trade Co., Ltd., we provide industrial belts that are built for performance, helping manufacturers optimize their processes across various sectors. This article explores how industrial belts contribute to improved efficiency and productivity—and why investing in the right belt matters.

________________________________________

Reliable Power Transmission for Consistent Output

Industrial belts are the primary method of power transmission in countless applications, from conveyor systems and compressors to machining tools and motors. A well-designed belt ensures smooth, consistent torque delivery, reducing fluctuations in performance and helping machines operate at optimal speeds.

Impact on efficiency:

- Minimizes energy loss due to slippage or misalignment

- Ensures stable machine speed, critical for precision manufacturing

- Helps reduce mechanical wear on connected components

When belts fail or lose tension, it disrupts the rhythm of production—causing slowdowns, errors, and unplanned downtime.

________________________________________

Reduction in Downtime and Maintenance Frequency

One of the biggest causes of production inefficiency is machine downtime, often triggered by worn-out or poorly matched belts. High-quality industrial belts are designed for durability, meaning fewer replacements and less frequent tension adjustments.

Key benefits:

- Extended service intervals, which means less time spent on maintenance

- Predictable wear patterns, allowing for proactive part replacement

- Lower long-term costs, even with higher initial investment

By choosing reliable belts suited to your application and environment, manufacturers can significantly cut down on unplanned interruptions.

________________________________________

Supporting High-Speed and Heavy-Load Operations

As factories scale production, they often require systems that can handle faster speeds and heavier loads. Belts reinforced with Kevlar cords, fiberglass, or advanced synthetic rubbers can transmit high levels of power without stretching or breaking.

Application examples:

- Packaging lines with high throughput

- Automated conveyor systems for logistics or sorting

- Pressing and molding equipment in plastics or metals

Strong, high-performance belts help these systems run faster without sacrificing safety or precision.

________________________________________

Energy Efficiency and Noise Reduction

Friction, misalignment, and slippage can waste energy and cause belts to operate noisily. Quality belts are engineered with low-friction materials and optimized profiles that reduce resistance.

Operational advantages:

- Lower energy consumption, helping reduce operational costs

- Quieter production lines, improving the working environment

- Less heat buildup, preserving both the belt and machinery

In energy-conscious facilities, choosing the right belt can contribute to broader sustainability goals.

________________________________________

Versatility Across Manufacturing Sectors

From automotive and textile production to electronics, food processing, and logistics, industrial belts are found in nearly every manufacturing sector. Each application may require specific features—chemical resistance, heat tolerance, anti-static properties, or FDA compliance.

At Shin-Ho International Trade Co., Ltd., we offer a wide range of industrial belts that serve:

- Heavy-duty manufacturing lines

- Clean environments like pharmaceutical and food production

- High-speed automation and robotics systems

By matching the belt’s design to your process needs, manufacturers can gain a competitive edge through improved system performance.

________________________________________

Conclusion: Small Component, Big Impact

Industrial belts may be small, but their impact on manufacturing efficiency and productivity is massive. The right belt:

- Reduces downtime

- Supports faster operations

- Enhances equipment reliability

- Lowers maintenance and energy costs

As a trusted supplier, Shin-Ho International Trade Co., Ltd. is committed to helping manufacturers select and implement belt solutions that drive real results.

Whether you need belts for heavy loads, high temperatures, or complex automation systems, our team is ready to help.

Visit our website or contact us today to learn more about how our industrial belt solutions can support your success.