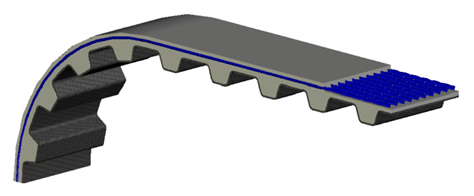

Synchronous Belt, Timing Belt

Material Selection:

You have the option to choose between two materials: Chloroprene Rubber (CR) or Hydrogenated Nitrile Butadiene Rubber (HNBR).

Chloroprene Rubber (CR): CR, also known as Neoprene, is a synthetic rubber known for its good weather resistance, ozone resistance, and oil resistance. It has moderate heat resistance and is typically used in various industrial applications that require oil resistance and moderate temperature resistance.

Hydrogenated Nitrile Butadiene Rubber (HNBR): HNBR is a special synthetic rubber obtained by hydrogenating Nitrile Butadiene Rubber (NBR). It offers excellent heat resistance, oil resistance, fuel resistance, and chemical resistance. HNBR is commonly used in applications requiring high temperature and oil resistance, such as automotive belts and seals.

Hydrogenated Nitrile Synchronous Belt with a lifespan exceeding 100,000 kilometers:

Hydrogenated Nitrile Synchronous Belts (HNBR belts) are renowned for their durability and long lifespan. They are often used in automotive engines as timing belts, needing to withstand high temperatures, rotational forces, and contact with oil and other contaminants. Under normal operating conditions, HNBR synchronous belts are designed to last over 100,000 kilometers. However, actual lifespan can vary depending on operating conditions, maintenance practices, and load requirements.